Pallet Racking Guide

Nature's Symphony

Welcome to the Alpha Omega Shelving Pallet Rack Resource Guide. This is your go-to hub for clear, practical, and up-to-date information on pallet racking systems and related material handling products. We regularly expand and refine these resources to ensure accuracy, industry relevance, and real-world usefulness. For the most precise details on your specific rack system, we always recommend verifying information with the original manufacturer.

If you have questions about your pallet rack system, need assistance identifying components, or want expert guidance on warehouse layout and design, contact our material handling team at (412) 276-1200. We’re here to help you optimize your space with confidence.

Nature's Symphony

Pallet Rack

Pallet rack is a core element of warehouse storage and material handling, designed to safely store palletized goods in a structured, high-density system. By taking advantage of vertical space, pallet racking allows facilities to maximize capacity, improve organization, and streamline product access. These systems are used across a wide range of industries, including distribution, manufacturing, and logistics, where efficient inventory management is essential. Though all pallet racks share the same purpose, each manufacturer designs its system with unique frame configurations, connection types, and hole patterns. The most common and versatile style is the teardrop rack, known for its distinctive teardrop-shaped holes that make installation and interchangeability easier. While some teardrop systems can be compatible across brands, mixing components is not typically recommended. To help identify your current racking style or manufacturer, refer to the Pallet Rack Identifier located at the bottom of this page.

Nature's Symphony

Components

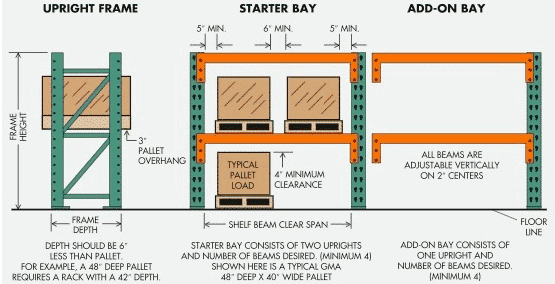

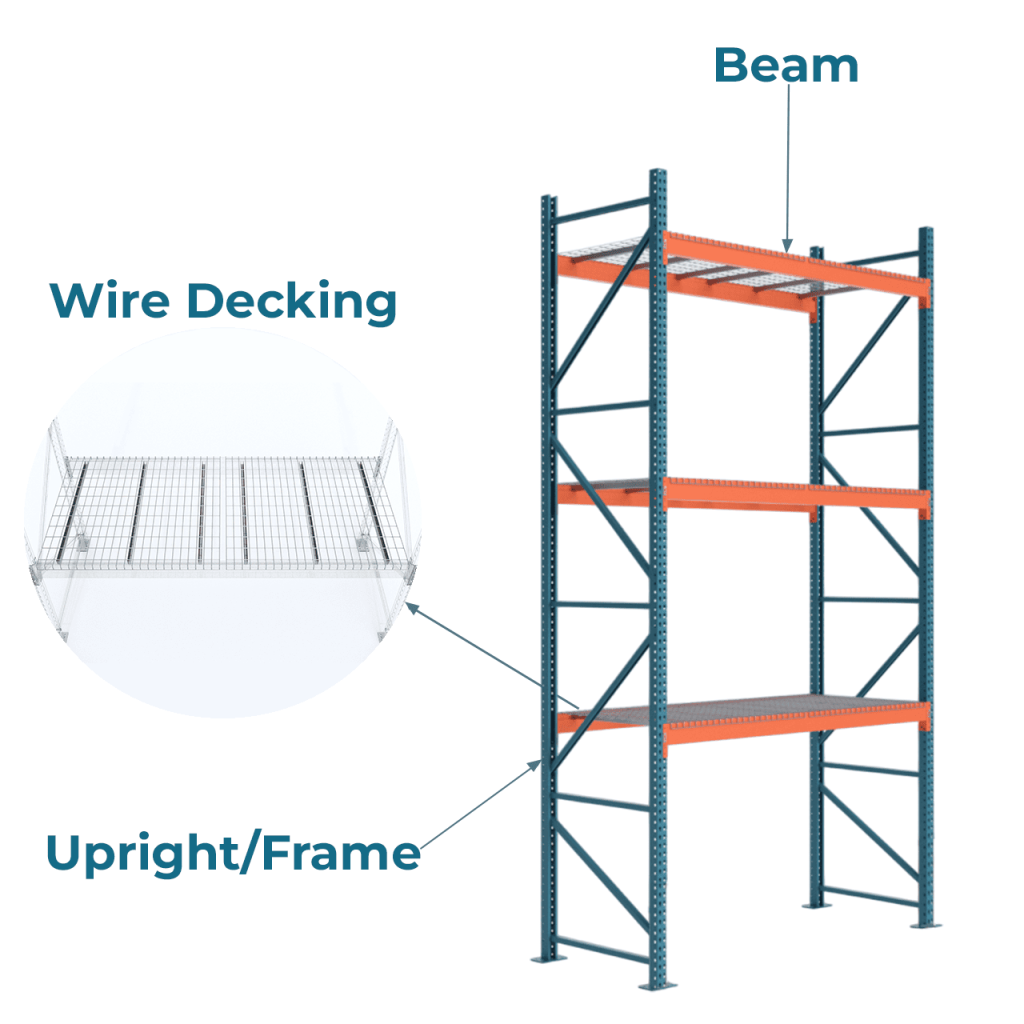

A pallet racking system contains three primary components: upright frames, beams, and wire decks.

Upright Frames

Upright frames form the foundation of any pallet rack system, supporting the weight of stored materials and connecting directly to the horizontal beams. Built from either roll-formed or structural steel, these vertical columns feature a series of precision-engineered punch holes that allow beams to be positioned at adjustable heights. This flexibility makes it easy to customize storage levels based on pallet size, product type, or equipment requirements. Designed for strength and stability, upright frames are the structural backbone that ensures the safety and performance of a warehouse racking system.

Cross Beams

Crossbeams create the horizontal support levels that connect upright frames and carry the pallet loads. They’re manufactured from durable roll-formed or structural steel and come in a range of lengths and load capacities to fit different warehouse applications. When properly installed, beams lock securely into the uprights to create a stable, heavy-duty shelving surface. Their design allows for easy reconfiguration, making crossbeams an essential component for adaptable warehouse storage systems that evolve with changing operational needs.

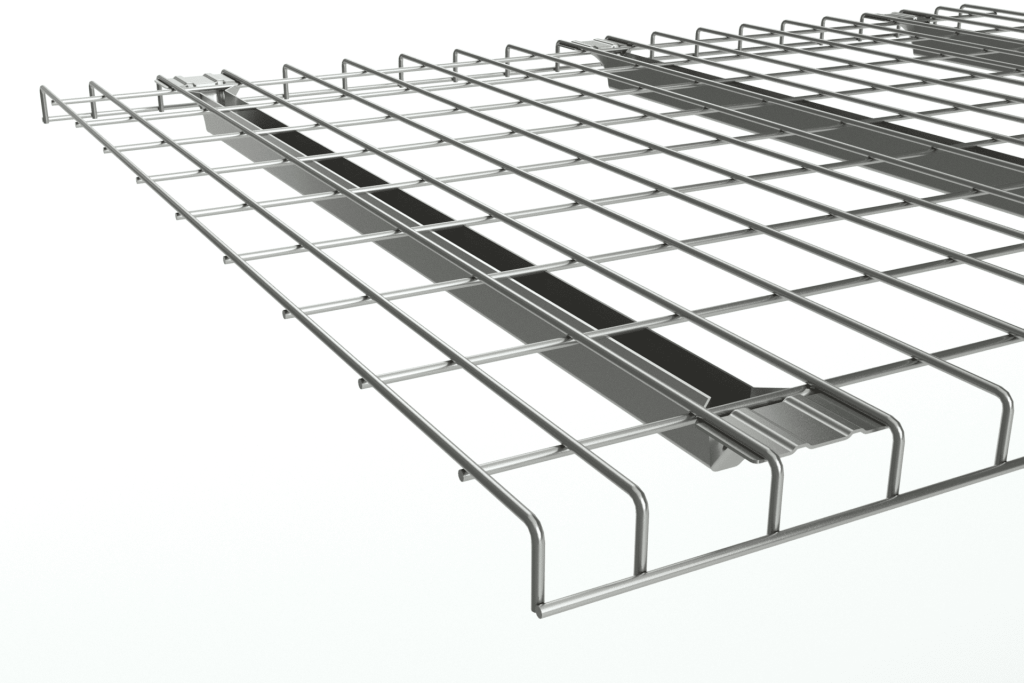

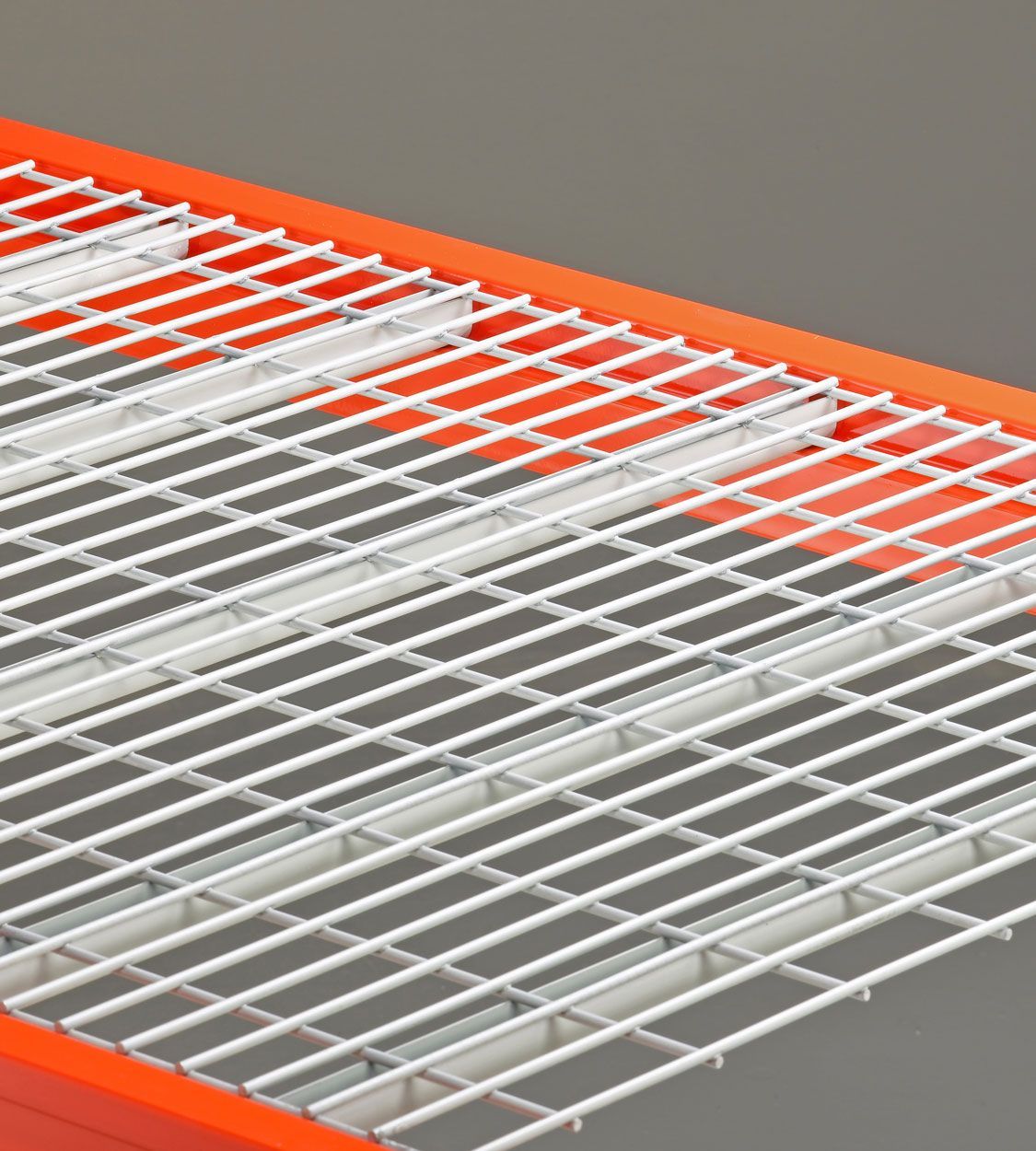

Wire Decking

Wire decking enhances both safety and functionality in pallet rack systems by providing a strong, open-grid surface that supports pallets and loose materials. The wire mesh design improves visibility and ventilation while allowing sprinkler systems to function effectively in case of fire. Decking also prevents items from falling through or shifting between beams, creating a safer, more organized storage environment. Built for durability and compliance with modern warehouse safety standards, wire decking is a simple but essential addition to any pallet rack configuration.

Styles of Wire Decking

Wire decking comes in several styles, each designed for specific pallet rack configurations and warehouse applications. The right choice depends on factors such as beam type, load capacity, and safety requirements. Below are three of the most common wire decking styles, with additional options like corrugated decking and punch deck covered in the pallet rack accessories section later on this page.

Flanged / Universal

This wire decking style is designed for pallet rack box beams, structural racks, and selective systems that do not have an inside step. The flared channel design allows it to rest securely on a wide range of beam types, making it a versatile and universal choice for many warehouse applications.

U-Channel Standard

U-channel decks are built for standard step beams with a 1 5/8-inch step and offer enhanced load strength compared to flare channel options. The support channels fit neatly into the beam step, creating a flush, reinforced surface for palletized goods. These decks are ideal for facilities prioritizing heavy-duty capacity and stability, though they are not compatible with beams lacking a step.

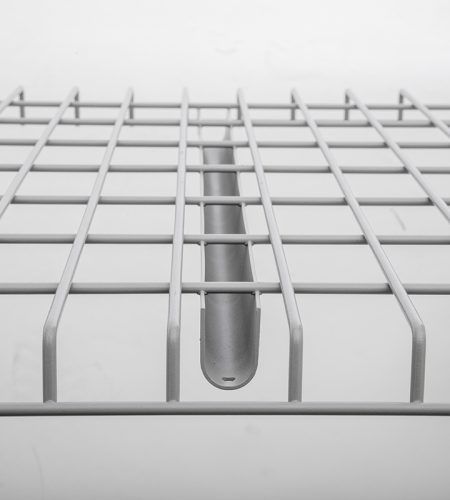

Inside Waterfall

Inside waterfall wire decking is used when the outer beam face must remain visible for barcode labels, safety markings, or load capacity stickers. Instead of wrapping over the outside of the beam, the waterfall edge drops inside the front face, maintaining a clean, accessible appearance. This design improves organization and labeling visibility while maintaining the same reliable support and airflow that wire decking provides.

Dividers

Pallet racking dividers improve warehouse organization, protect inventory, and enhance safety. Alpha Omega Shelving provides durable, customizable dividers for industrial storage and efficient inventory management.

Hanging Shelf Divider

Hanging shelf dividers will hang from the wire decking above and connect securely to the deck at the beam level below, creating individual storage sections that improve visibility, accessibility, and inventory management within a rack system.

Standing Shelf Divider

Designed to create clear separation between products on a pallet rack beam level, these dividers clip directly into the wire decking and lock securely in place. They help maintain organized storage, improve visibility, and prevent items.

M Dividers

M dividers are used to organize and separate products stored vertically within pallet rack bays. Shaped like the letter “M,” these dividers mount to the wire decking and provide individual storage lanes for items such as doors, panels, or sheets. They help maintain order, prevent product damage, and improve picking efficiency.

General Accessories

Warehouse accessories can improve storage organization, protect inventory, and enhance safety. Alpha Omega Shelving offers durable, reliable solutions for every facility.

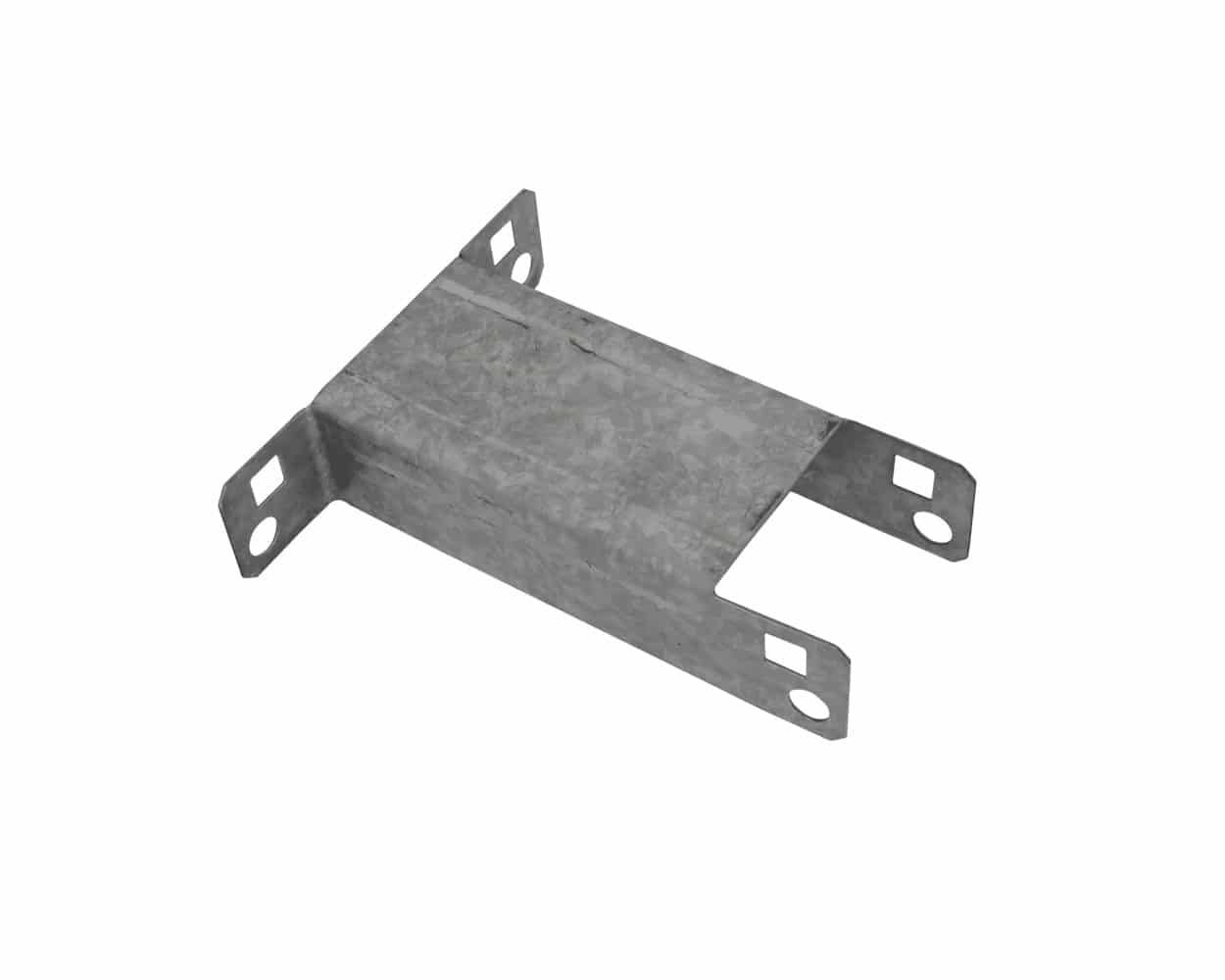

Row Spacer

Row spacers are used to stabilize and align back-to-back rows of pallet racking while maintaining proper space for safety and ventilation. They help ensure consistent spacing, improve rack stability, and support compliance with fire safety and warehouse design standards.

Wall Ties

Pallet rack wall ties anchor single rows of racking to the warehouse wall, providing added stability and alignment. They help prevent movement or tipping, ensuring a secure and code-compliant storage system in areas where back-to-back rows are not used.

Pallet Stops

Pallet stops are safety components installed at the back of pallet rack levels to prevent pallets from being pushed too far and falling through or damaging walls and product. They provide a simple yet effective way to maintain proper pallet placement and protect both inventory and racking structure.

Rack Back

Rack backing is a protective barrier system mounted to the back of pallet racking to prevent products or pallets from falling into aisles or work areas. Commonly made from welded wire mesh panels, rack backing enhances warehouse safety by containing inventory while still allowing visibility and airflow throughout the storage system.

Decking

Pallet racking decking provides stable, secure surfaces for stored items, improving safety and organization. Alpha Omega Shelving offers durable decking solutions for warehouses, industrial facilities, and commercial spaces.

Wire Mesh Deck

Wire mesh decking is a metal grid panel designed to sit on pallet rack beams, creating a safe and stable surface for storing pallets, boxes, or loose items. It improves load support, increases fire safety by allowing sprinkler water flow, and enhances visibility and airflow throughout the rack system.

Corrugated Deck

Corrugated decking is a solid steel panel with a ribbed design that provides a strong, durable surface for pallet rack shelves. Unlike wire mesh, corrugated decking offers complete coverage, making it ideal for storing small parts, cartons, or irregularly shaped items that might slip through open grid decks. It also enhances shelf rigidity and load distribution across the racking system.

Pallet Supports

Pallet supports are steel channels that drop between pallet rack beams to provide additional reinforcement and stability for stored pallets. They help prevent pallets from sagging or falling through when not fully supported by the beams, improving overall safety and load distribution. Pallet supports are commonly used with wire decking or as a standalone option in selective rack systems.

Punch Deck

Punch Deck is a steel decking option designed with a perforated surface that allows for airflow, light penetration, and fire sprinkler efficiency. It provides a solid yet ventilated platform for storing pallets, cartons, or irregular loads. Known for its strength and durability, Punch Deck is often used in applications requiring a smooth, debris-free surface, such as food storage, retail, or clean warehouse environments.

Safety Products

Safety products are designed to help prevent any damages to racking, protect inventory, and enhance safety. Alpha Omega Shelving provides a large variety of safety options to ensure the most protection for your racking.

Column Guard

Column guards are protective barriers designed to shield pallet rack uprights from forklift and pallet impact. Installed at the base of each frame, they absorb and deflect collisions that could compromise rack integrity or lead to costly repairs. Available in both steel bolt-on and wrap-around styles, column guards are a simple and effective way to extend the life of your racking system and enhance overall warehouse safety.

End Row Guard

End row guards protect the ends of pallet rack aisles from impacts caused by forklifts, pallet jacks, and other warehouse equipment. Positioned at the outermost frames, these guards take the brunt of accidental contact, preventing damage to racking structures and maintaining overall system stability. Built from heavy-duty steel, end row guards are a cost-effective safety measure that extends the life of your pallet rack investment while keeping aisles safe and organized in high-traffic warehouse environments.

Guardrail

Guardrails provide a strong physical barrier that protects personnel, equipment, and pallet racking from forklift or vehicle impact in busy warehouse environments. Commonly installed around pedestrian walkways, machinery, and storage areas, guardrails help define safe traffic zones and prevent costly damage or injury. Constructed from heavy-duty steel and anchored securely to the floor, they offer long-term durability and visibility, making them an essential component of any warehouse safety system.

Handrail

Handrails create safe walking zones for employees by providing a secure barrier between pedestrian areas and active equipment traffic. Commonly installed along mezzanines, platforms, stairways, and walkways, handrails help prevent falls and guide movement through busy warehouse environments. Built from durable steel or aluminum, they deliver long-lasting stability and compliance with safety standards, ensuring both protection and organization throughout your facility.

Engineered Pallet Rack Systems

Selective Pallet Rack

Standard selective pallet rack is the most widely used warehouse racking system, known for its versatility and straightforward design. This system allows direct access to every pallet, as each load is stored in a single-deep lane without obstruction. The key difference between manufacturers lies in the beam-to-frame connection, identified by the punch hole pattern on the uprights, with teardrop racking being the most popular and interchangeable option. Selective pallet rack is available in both roll-formed and structural steel styles, making it adaptable for everything from light-duty storage to demanding industrial applications.

Push Back Rack

Push-back rack systems are a high-density pallet storage solution engineered to increase capacity and efficiency within warehouse and distribution environments. Pallets rest on a series of nested carts that glide along inclined rails, allowing each new pallet to push the previous load backward into the lane. When a pallet is removed, the remaining pallets automatically move forward to the pick face, ensuring smooth and reliable product rotation.

Drive-In Rack

Drive-in rack systems are designed for maximum storage density, making them ideal for high-volume, low-SKU warehouse environments.

Pallet/Gravity Flow Rack

Pallet flow rack, also known as gravity flow rack, is a dynamic storage system that uses sloped roller tracks to move pallets automatically from the loading side to the picking side.

Carton Flow Rack

Carton flow rack is a high-efficiency shelving system designed for small to medium-sized products stored in bins, totes, or cartons.

Cantilever Rack

Cantilever rack is a versatile storage system designed for long, bulky, or irregularly shaped items such as lumber, piping, tubing, and sheet goods.

Automated Storage and Retrieval Systems (ASRS)

Automated Storage and Retrieval Systems (ASRS) are mechanized storage solutions designed to optimize warehouse efficiency, reduce labor costs, and maximize space utilization.

For reliable pallet racking and material handling solutions, contact Alpha Omega Shelving at (412) 276-1200